.svg)

.svg)

PLC Programming of Siemens using PLC Controller Examples with SCADA.

For Electrical, Electronics, Instrumentation Engineers

Course Type :

₹ 20050

Topic 1 l Introduction about Industrial Automation

Topic 1 l Introduction about Industrial Automation

Topic 2 | Introduction about Input Field Devices

Topic 2 | Introduction about Input Field Devices

Topic 3| Introduction about Output Field Devices

Topic 3| Introduction about Output Field Devices

Topic 4 | Interlocking

Topic 4 | Interlocking

Topic 5 | Logical Gates

Topic 5 | Logical Gates

Topic 6 | Introduction about PLC

Topic 6 | Introduction about PLC

Topic 7 | Introduction about Ladder Logic

Topic 7 | Introduction about Ladder Logic

Topic 8| Working with PLC Software TIA

Topic 8| Working with PLC Software TIA

Topic 9 | Memory Concept with PLC

Topic 9 | Memory Concept with PLC

Topic 10 | Timers

Topic 10 | Timers

Topic 11 | Counters

Topic 11 | Counters

Topic 12 | Comparator Functions

Topic 12 | Comparator Functions

Topic 13 | Jump & MCR Functions

Topic 13 | Jump & MCR Functions

Topic 14 | Word Logic Functions

Topic 14 | Word Logic Functions

Topic 15 | Interfacing I/O Field devices with PLC

Topic 15 | Interfacing I/O Field devices with PLC

Topic 16 | PLC Programming Based Project

Topic 16 | PLC Programming Based Project

Topic 17 | Introduction about SCADA

Topic 17 | Introduction about SCADA

Topic 18 | Introduction about Siemens SCADA Wincc

Topic 18 | Introduction about Siemens SCADA Wincc

Topic 19 | working with Communication Internal Tags with SCADA

Topic 19 | working with Communication Internal Tags with SCADA

Topic 20 | Working with Various Objects

Topic 20 | Working with Various Objects

Topic 21 | Graphics Library in SCADA

Topic 21 | Graphics Library in SCADA

Topic 22 | Object Animation Creation

Topic 22 | Object Animation Creation

Topic 23 | Projects on Seven Segment Display

Topic 23 | Projects on Seven Segment Display

Topic 24 | Develop SCADA Projects

Topic 24 | Develop SCADA Projects

Roles in industry

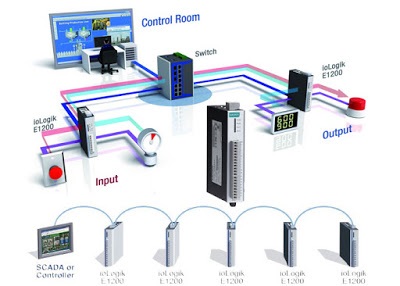

PLCs and SCADA are used in many machines, in many industries. Some example of industries are given below:

Course Highlights

Copyright © 2025 ABCTrainings - All rights reserved