.svg)

.svg)

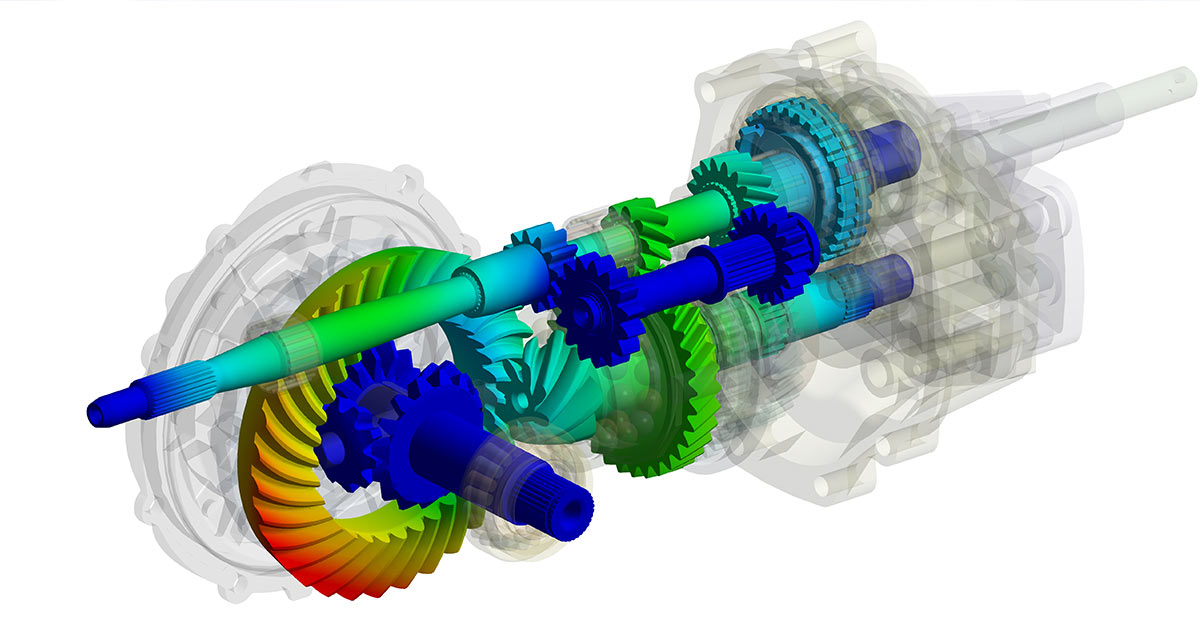

The Ansys Workbench platform lets you integrate data across engineering simulations to create more accurate models more efficiently.

For Mechanical and Automobile Engineers

Course Type :

₹ 19534

Topic 1 | Introduction to ANSYS Workbench

Introduction to ANSYS Workbench

Topic 2| Sketching And Part Modeling

| Sketching And Part Modeling

Topic 3 | Solid modeling

Solid Modeling

Topic 4 | Assembly Features

Topic 4 | Assembly Features

Topic 5 | Modeling techniques

Topic 5 | Modeling Techniques

Topic 6 | Defining Material Properties

Topic 6 | Defining Material Properties

Topic 7 | Meshing

Topic 7 | Meshing

Topic 8 | Static Structural Analysis

Topic 8 | Static Structural Analysis

Topic 9 | Wizard and Tools

Topic 9 | Wizard And Tools

Topic 10 | Surface and line models

Topic 10 | Surface And Line Models

Topic 11 | Natural Frequencies

Topic 11 | Natural Frequencies

Topic 12 | Buckling Loads

Topic 12 | Buckling Loads

Topic 13 | Thermal Analysis

Topic 13 | Thermal Analysis

Topic 14 | Thermal Stress

Topic 14 | Thermal Stress

Course Description

ANSYS Mechanical is a finite element analysis tool that is widely used for analyzation and solving complex mechanical problems. The tool is efficient in predicting the behavior of the components in the manufacturing industry and real-world environments. ANSYS globally supports engineering simulation with the delivery of high-quality products developed in less time through the better information-based process.

Course objectives

ANSYS training course aims to explain the basics of ANSYS, Finite Element Modeling (FEM), and Finite Element Analysis (FEA). The curve of learning will elevate from various stages, which includes pre-processor, solution, and post-processor. The course will also explain on ways to conduct advanced structural analysis that is also described in hands-on sessions.

Roles in industry

The software is being used in wide range of industries to analyze various performance parameters such as signal integrity, electromagnetic interference, thermal issues, and mechanical failure.

Course Highlights

Copyright © 2025 ABCTrainings - All rights reserved