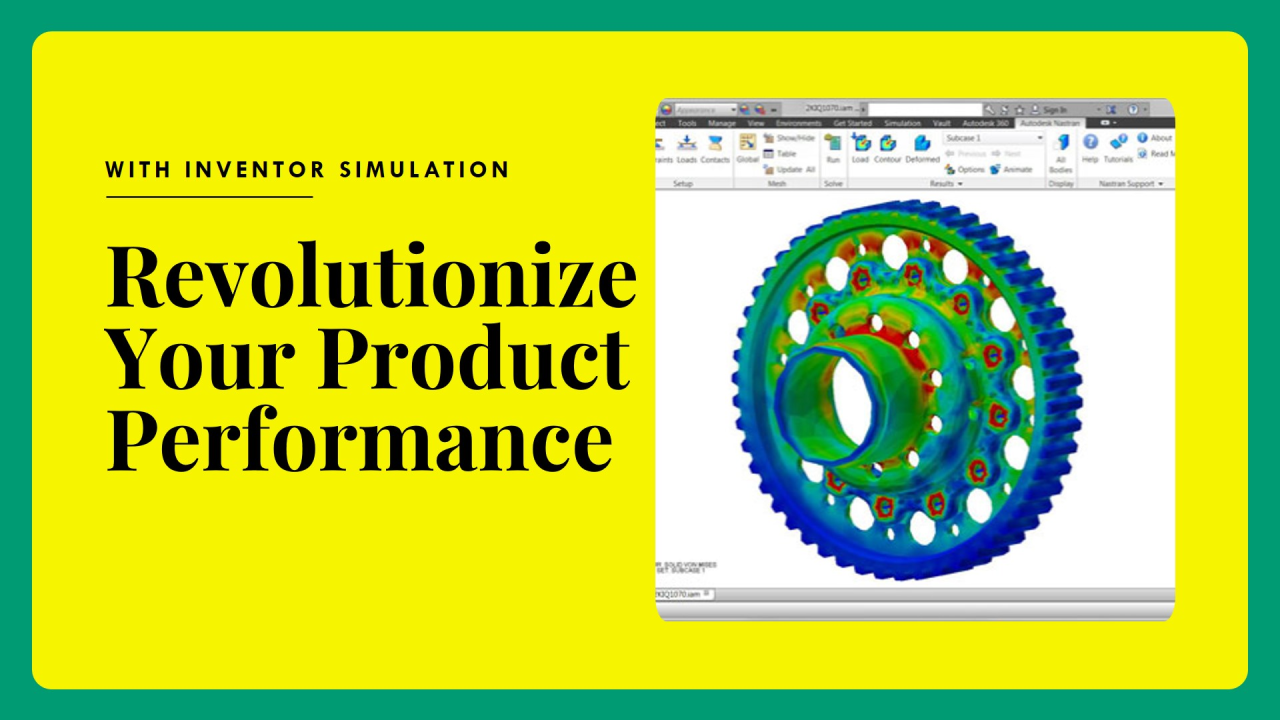

Inventor Simulation, a powerful tool embedded within Autodesk Inventor, is revolutionizing the product design process. By providing engineers with the ability to virtually test and analyze product performance, it empowers them to make informed decisions early in the design cycle, reducing costs and accelerating time-to-market.

Key Benefits of Inventor Simulation:

- Early Design Validation: Identify potential design flaws and weaknesses before costly physical prototypes.

- Optimized Performance: Refine designs to achieve optimal performance parameters like strength, durability, and efficiency.

- Reduced Prototyping: Minimize the number of physical prototypes required, saving time and resources.

- Improved Product Quality: Deliver products that meet or exceed customer expectations through rigorous simulation testing.

Common Simulation Types in Inventor:

- Structural Analysis: Evaluate a product's ability to withstand loads and stresses.

- Motion Analysis: Simulate product movement and interactions with other components.

- Thermal Analysis: Analyze temperature distribution and heat transfer within a product.

- CFD (Computational Fluid Dynamics): Simulate fluid flow around and within products.

Real-World Applications:

- Automotive Industry: Crash testing, aerodynamics, engine performance optimization.

- Aerospace Industry: Structural integrity analysis, vibration testing, thermal management.

- Consumer Products: Durability testing, ergonomic analysis, product safety assessment.

- Machinery and Equipment: Stress analysis, fatigue life prediction, vibration analysis.

By leveraging Inventor Simulation, engineers can:

- Increase design confidence: Make data-driven decisions based on simulation results.

- Accelerate innovation: Explore multiple design iterations efficiently.

- Enhance product reliability: Identify and address potential failure points.

- Optimize manufacturing processes: Improve product manufacturability through simulation-driven design.

In conclusion, Inventor Simulation is an indispensable tool for modern product development. By integrating simulation early in the design process, engineers can create superior products that meet market demands while minimizing costs and time-to-market.

Would you like to delve deeper into a specific simulation type or industry application?

Inventor Simulation analysis

#InventorSimulation #ProductDesign #CAE #FEA #CFD #Engineering #Simulation #DesignOptimization

Join the ABC Trainings Community!

Expand your design and tech knowledge by following us on social media for daily tips, industry insights, and exclusive announcements.

Don't forget to share this article with your network!

By sharing valuable content, we can help more people develop their design and tech skills. Let's spread the knowledge together!

#ABCTrainings #DesignChallenge #TechSkills #Upskilling

Leave a Comment Below!

We value your feedback and questions. Let us know your thoughts on today's topic in the comments section below. We're here to create a collaborative learning environment for everyone.

.svg)

.svg)