.svg)

.svg)

In today's competitive world, efficiency, accuracy, and speed are king. For mechanical engineers, this translates to a reliance on a powerful trinity of software: Computer-Aided Design (CAD), Computer-Aided Engineering (CAE), and Computer-Aided Manufacturing (CAM).

ABC Trainings is proud to offer a comprehensive suite of courses to equip you with mastery in these essential tools. But why are these software programs so critical in the modern engineering landscape? Let's delve into their individual strengths and the collective impact they bring:

CAD CAM & CAE design courses at abc Trainings

Imagine a world where intricate 3D models materialize with a few clicks. CAD software makes this a reality. It streamlines the design process, allowing for:

Enhanced Accuracy and Precision: Eliminate errors and inconsistencies with digital drafting tools. Effortless Design Iteration: Rapidly modify and refine your designs, fostering creativity and innovation. Seamless Collaboration: Share and collaborate on designs in real-time with colleagues across locations. Automated Documentation: Generate bills of materials and manufacturing drawings with a single click.

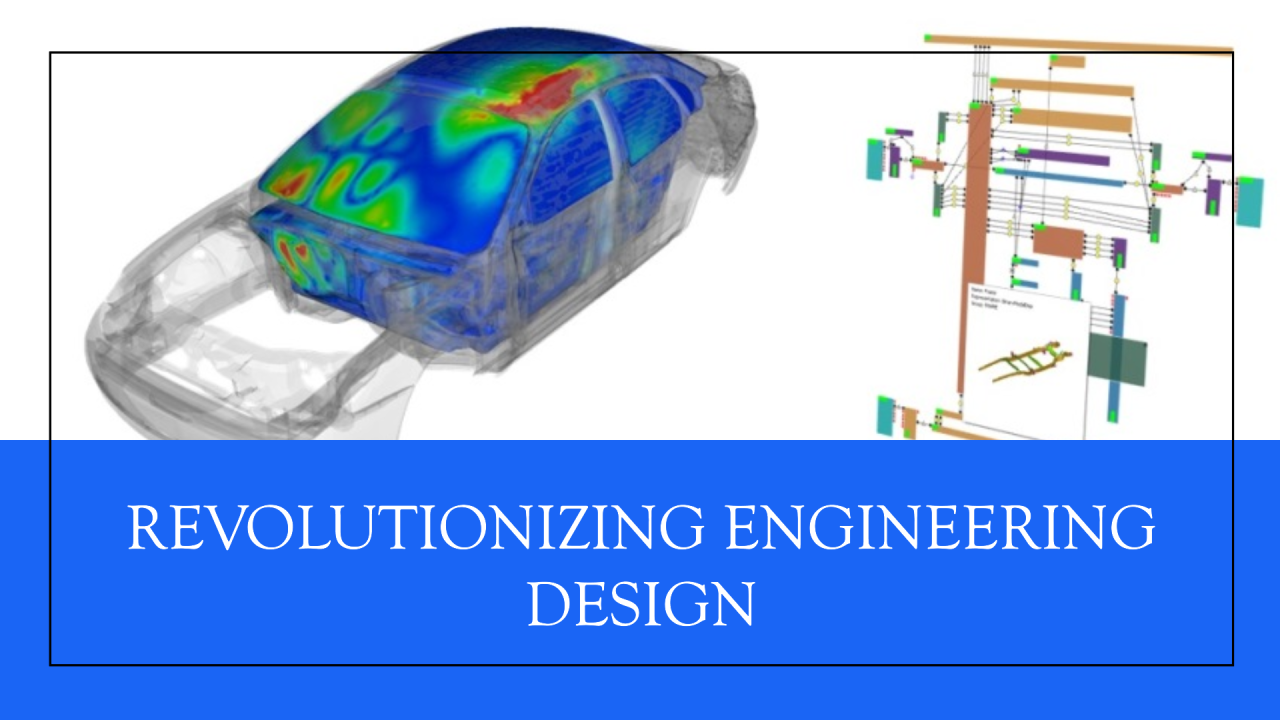

CAE software takes design a step further by simulating real-world conditions. Imagine testing a product's stress tolerance, thermal performance, or fluid dynamics before ever building a physical prototype. CAE offers:

Reduced Development Costs: Virtual testing eliminates the need for expensive physical prototypes. Improved Design Optimization:Identify and address potential issues early in the design phase. Enhanced Product Performance: Ensure your designs meet functional requirements before production. Advanced Material Exploration: Test the behavior of different materials within your design.

CAM software bridges the gap between design and manufacturing. It translates digital models into instructions for Computer Numerical Control (CNC) machines, automating the production process. This allows for:

Increased Manufacturing Efficiency:Streamline production with automated toolpath generation. Reduced Manufacturing Errors: Minimize human error by relying on precise digital instructions. Enhanced Product Consistency: Ensure consistent quality across every manufactured part. Rapid Prototyping Capabilities:Facilitate faster creation of functional prototypes for testing.

The Perfect Harmony: CAD, CAE & CAM in Action

These three software programs work best when used in tandem. Imagine designing a complex engine component in CAD, then simulating its performance under stress in CAE, before generating precise instructions for its manufacture using CAM. This integrated approach empowers engineers to:

Equipping Yourself for Success

By mastering CAD, CAE, and CAM software, you'll be well-positioned to thrive in today's demanding engineering environment. ABC Trainings offers a variety of courses to equip you with the skills you need to excel. Visit our website today to learn more and take your engineering career to the next level!

Copyright © 2025 ABCTrainings - All rights reserved